Paper Cutters & Trimmers

17 products

Showing 1 - 17 of 17 products

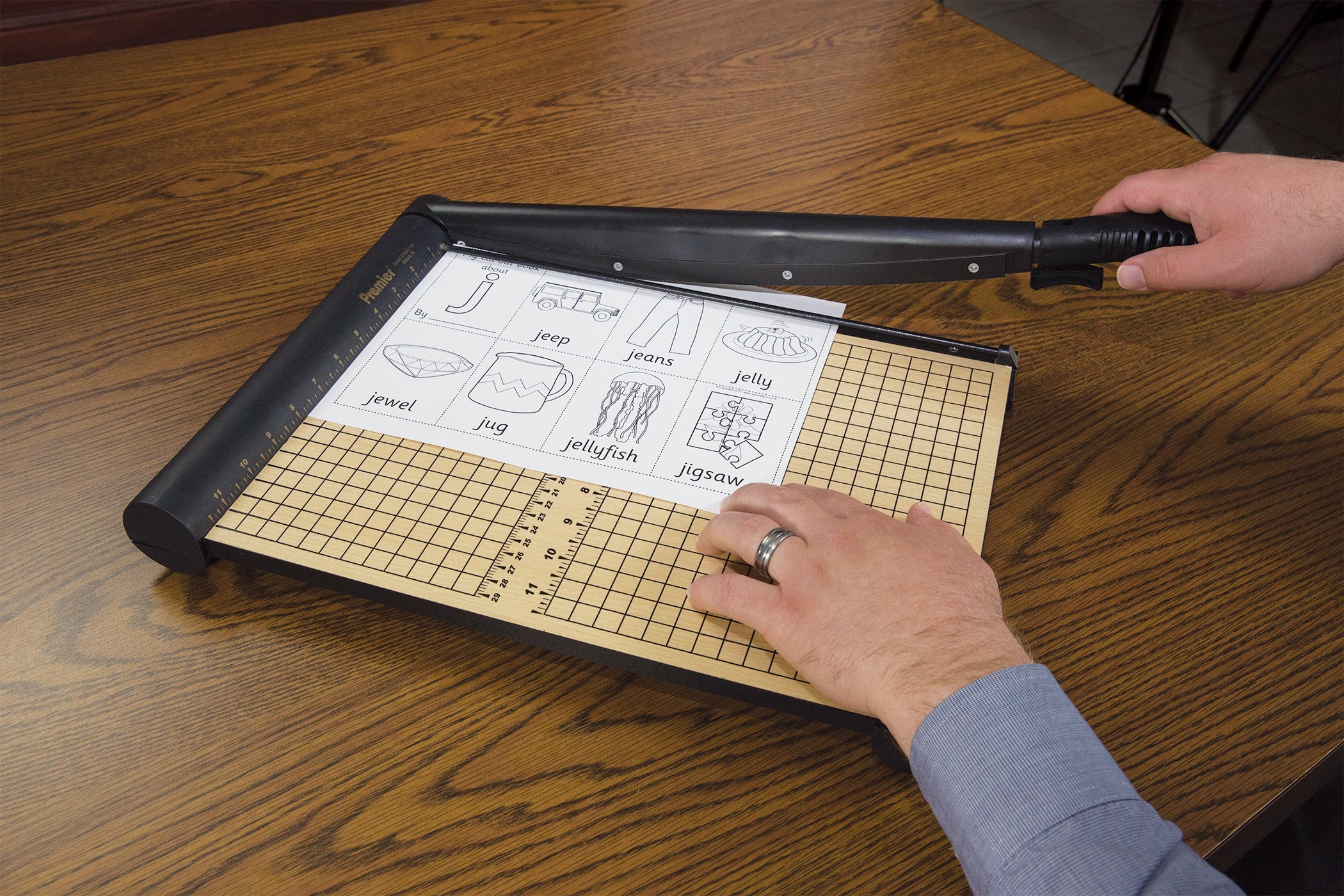

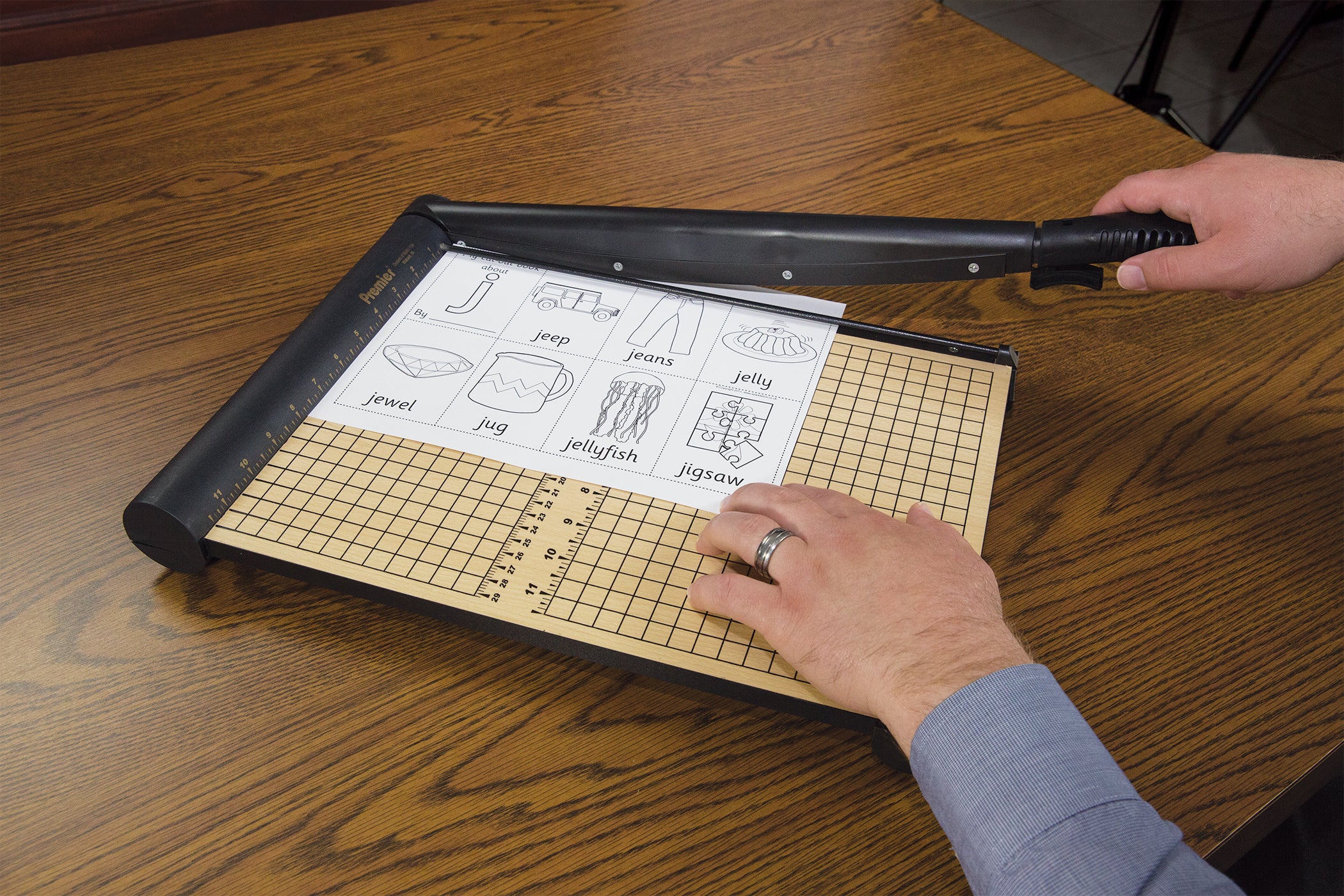

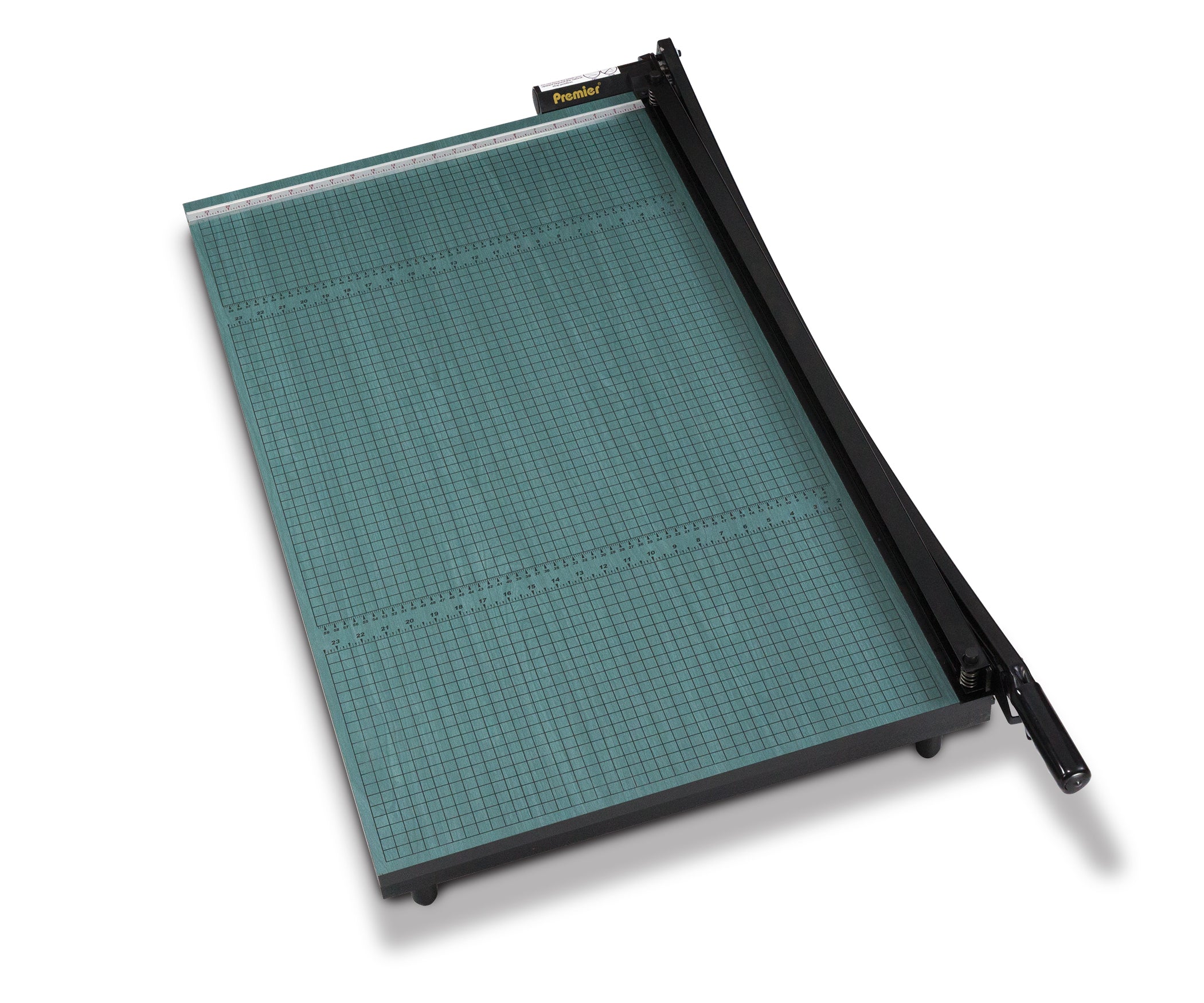

The professional cutting machines feature rotary and guillotine paper cutters from the Martin Yale Premier Series and ream cutters and stack cutters for heavy-duty, industrial use. Sturdy, durable, and self-sharpening blades will ensure years of reliable performance. With a variety of cutting lengths and capacities, Martin Yale cutters are designed to handle all of your paper-cutting needs.

Showing 1 - 17 of 17 products

Display

View

Save $283.74

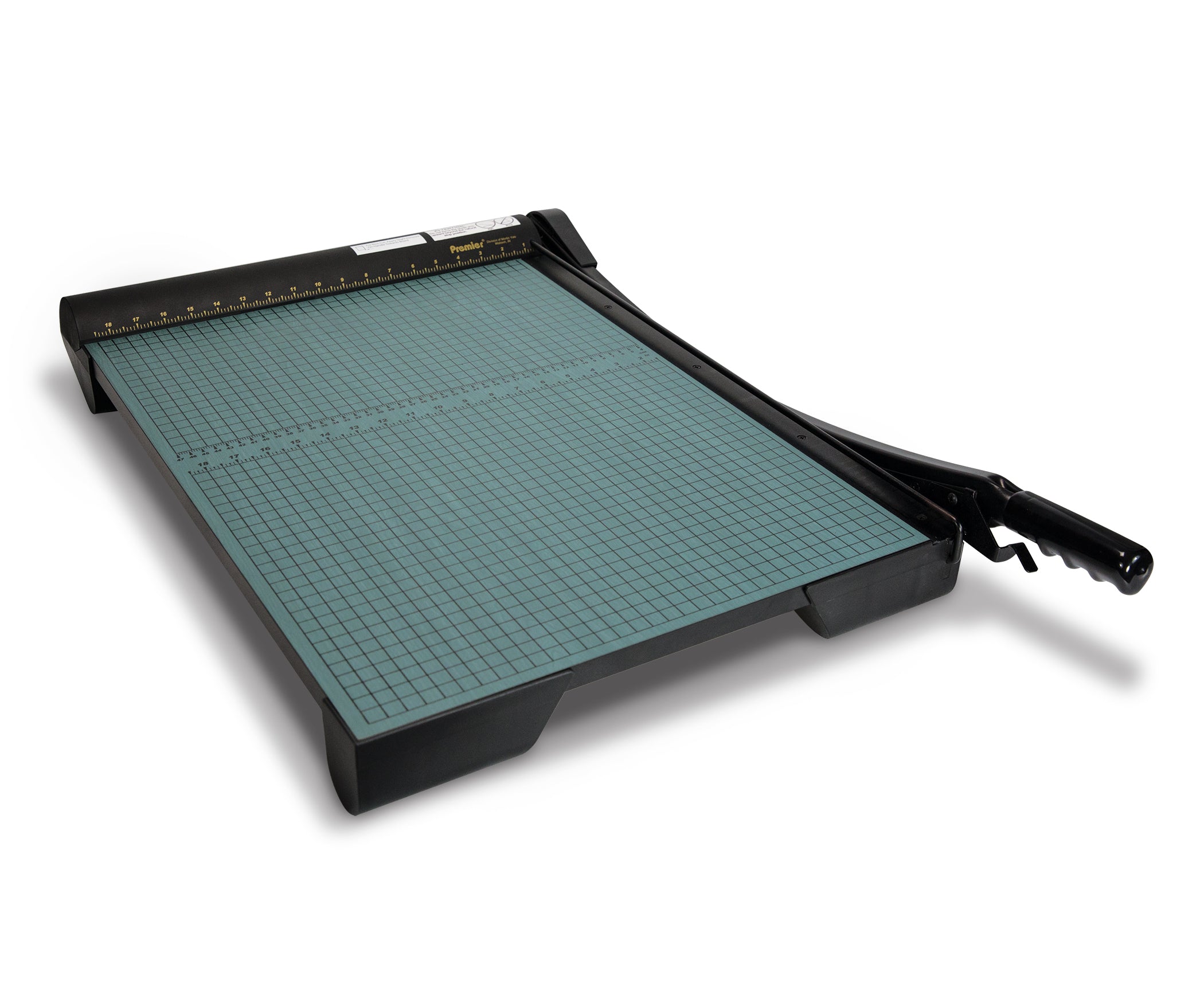

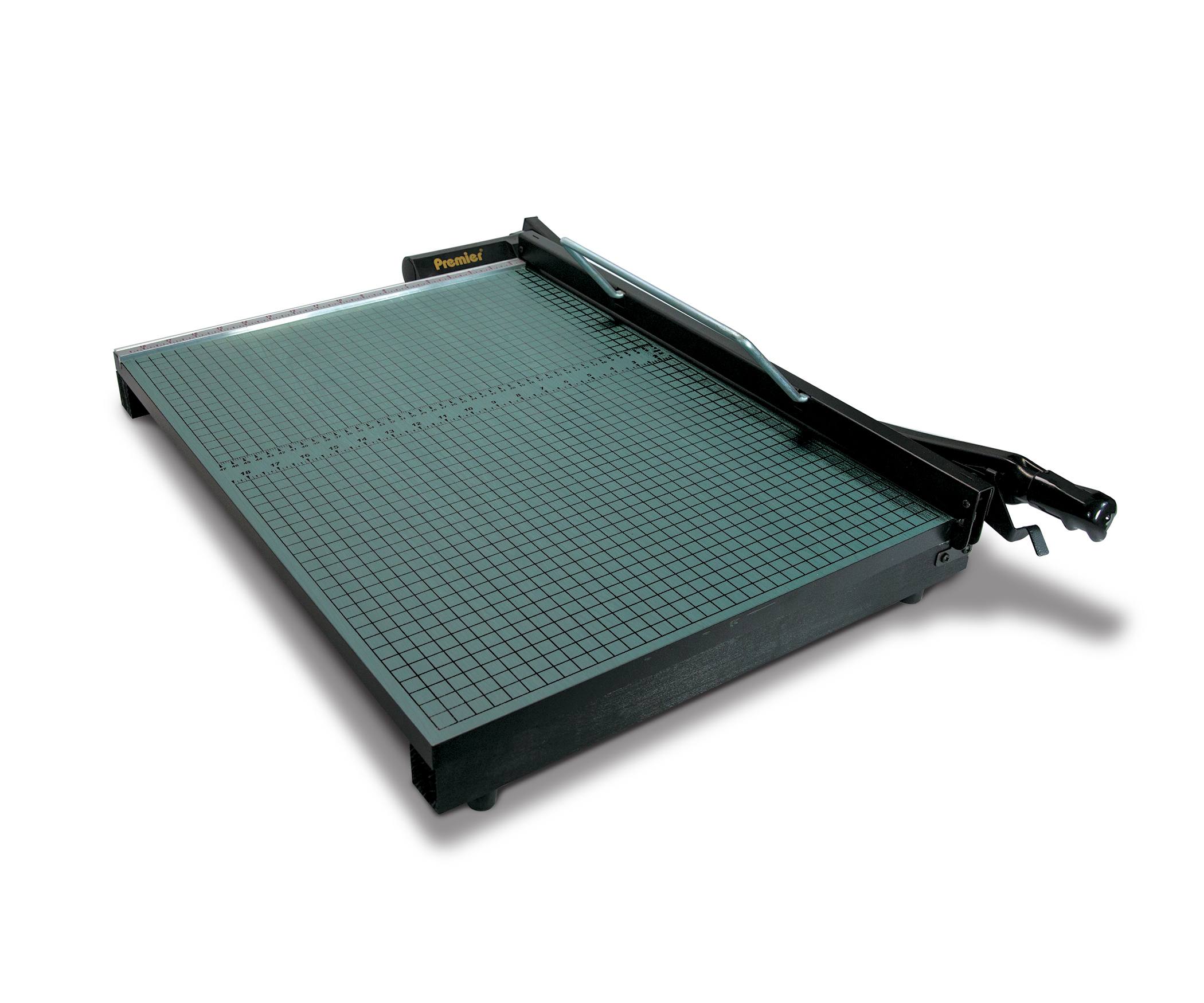

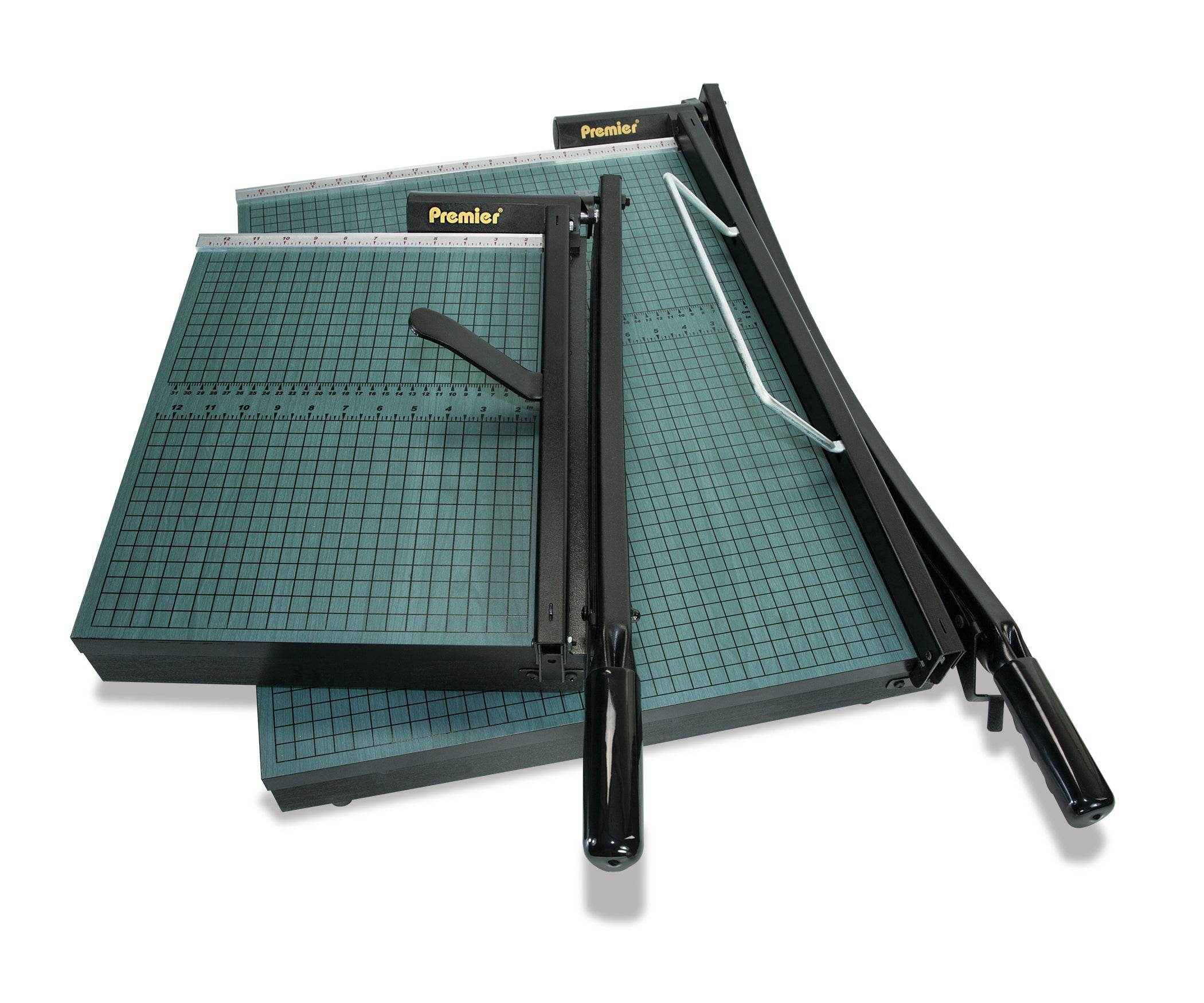

Premier

Martin Yale Premier GreenBoard Heavy-Duty 24" Paper Trimmer

Sale price$282.69

Regular price$566.43

Save $211.46

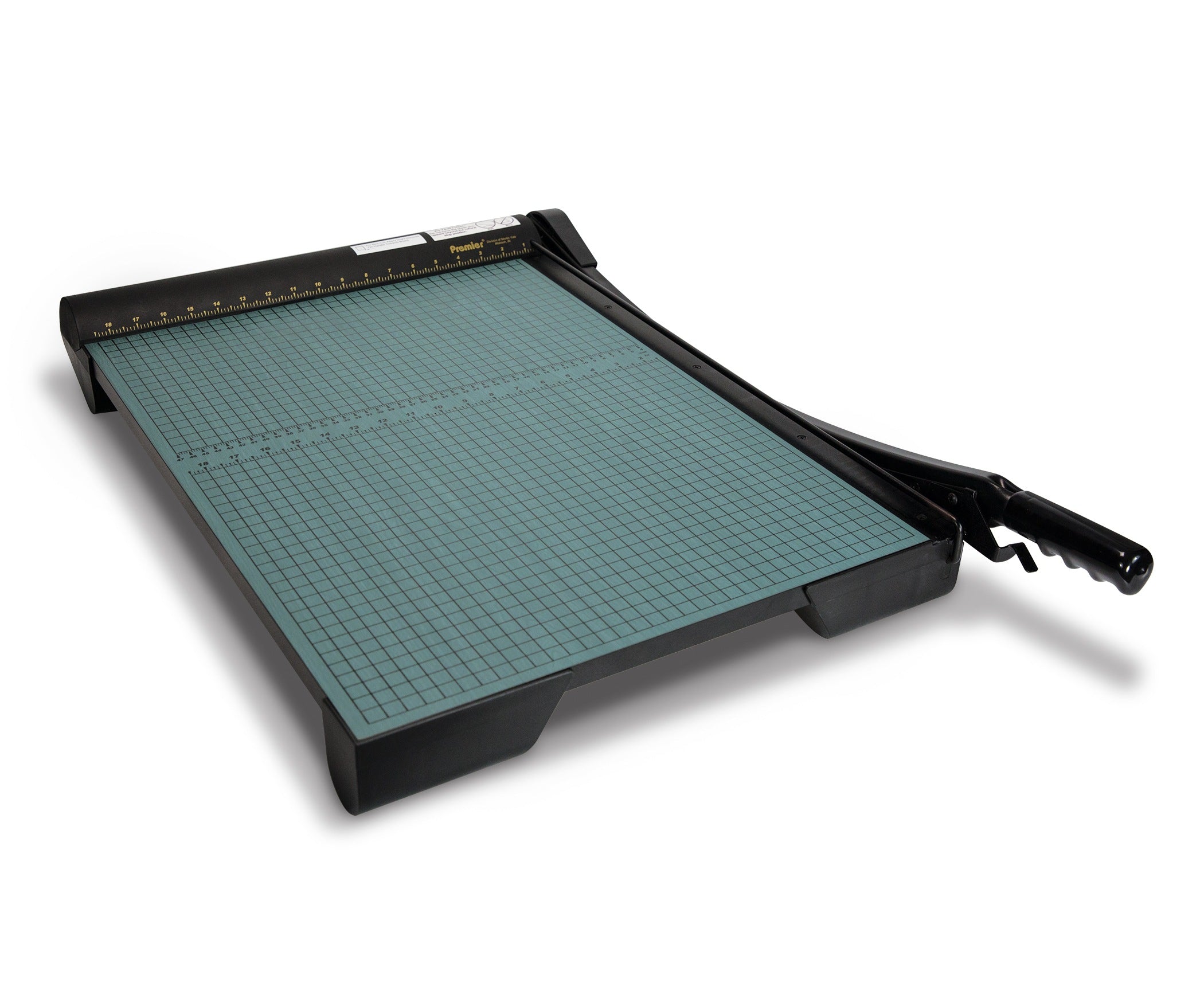

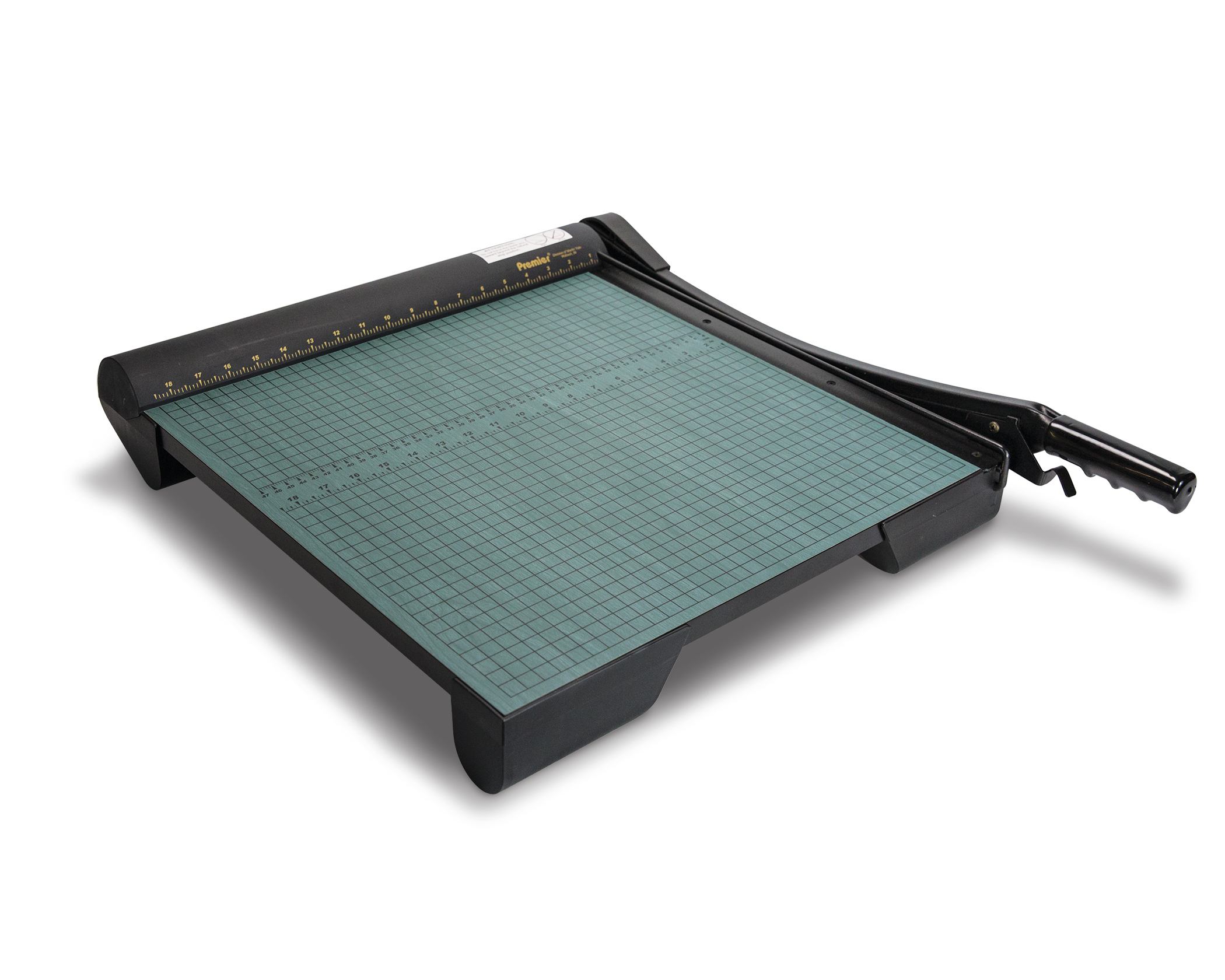

Premier

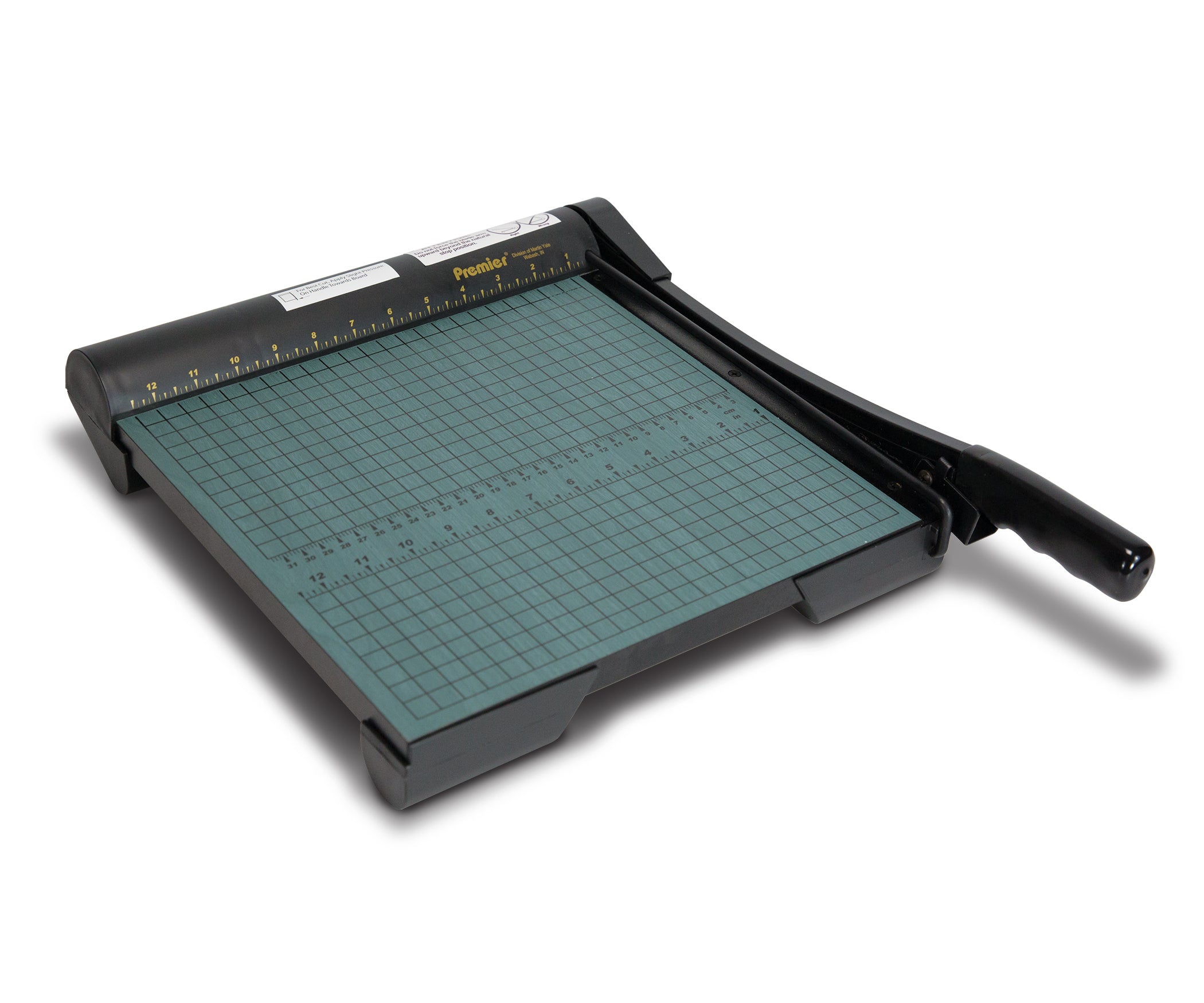

Martin Yale Premier GreenBoard Heavy-Duty 18" Paper Trimmer

Sale price$201.48

Regular price$412.94

Save $450.80

Premier

Martin Yale Premier StakCut Heavy-Duty 24" Paper Trimmer

Sale price$338.41

Regular price$789.21

Save $627.72

Premier

Martin Yale Premier GreenBoard Heavy-Duty 36" Paper Trimmer

Sale price$661.36

Regular price$1,289.08

Save $296.30

Premier

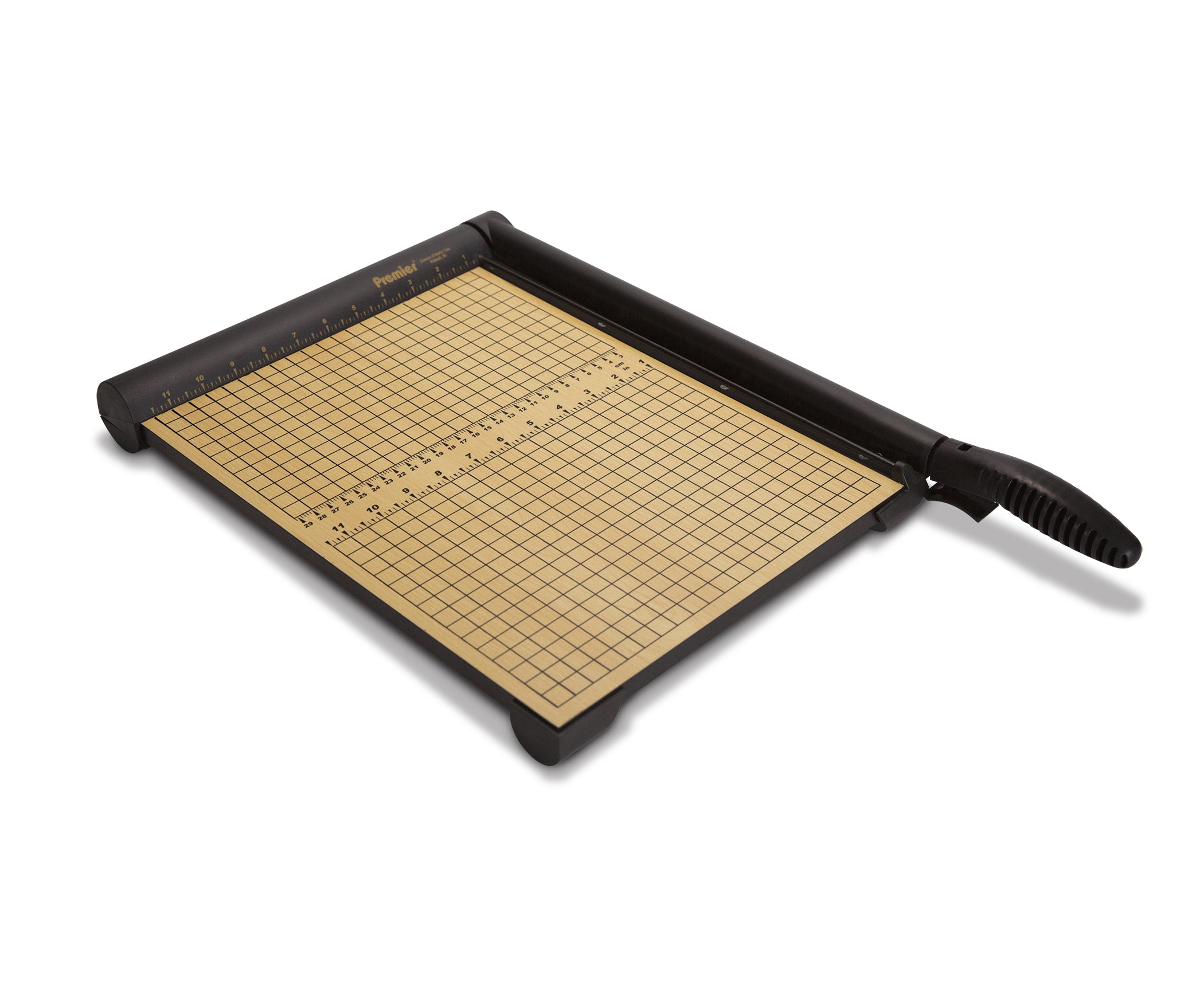

Martin Yale Premier StakCut Heavy-Duty 15" Paper Trimmer

Sale price$219.88

Regular price$516.18

Save $439.87

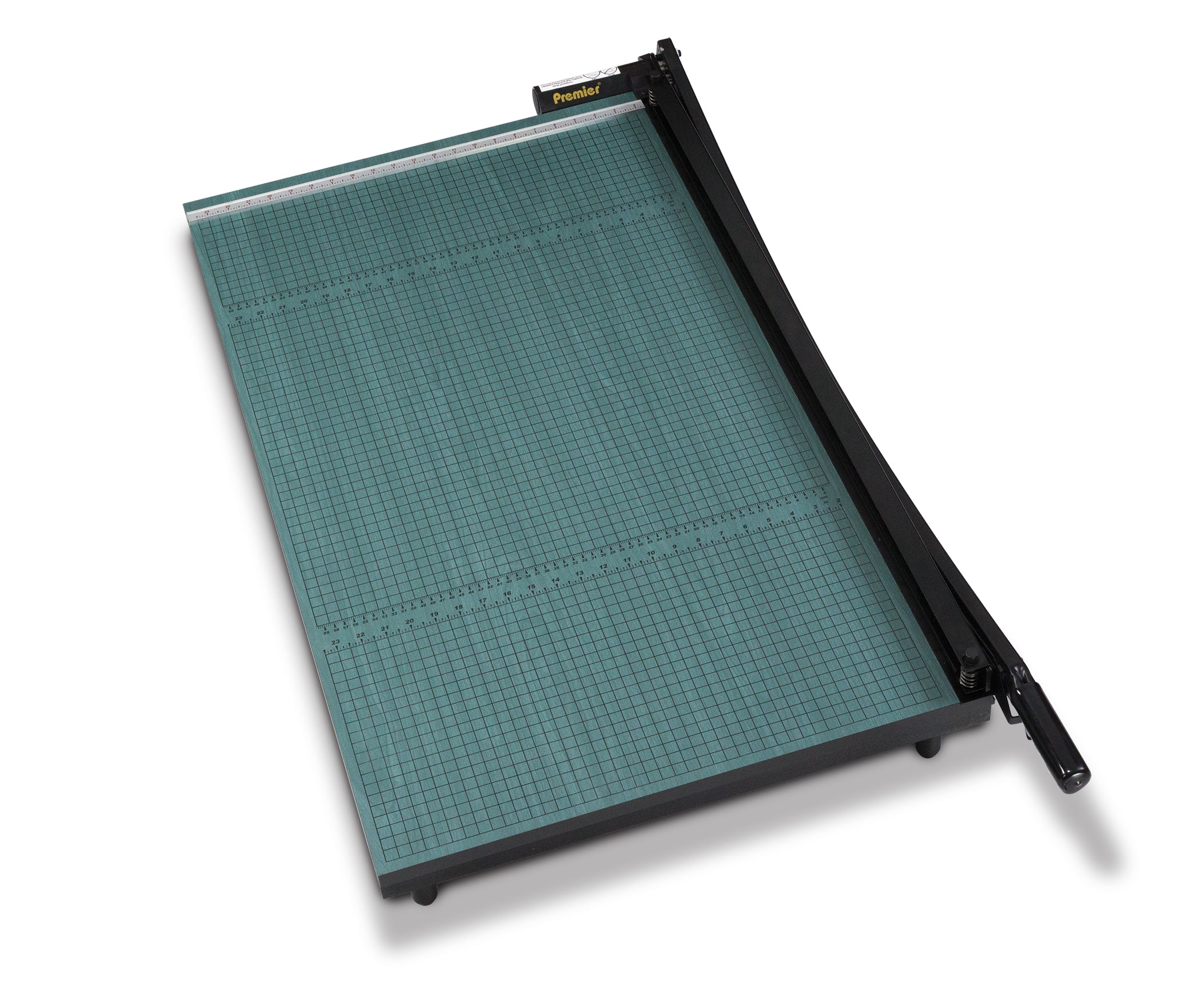

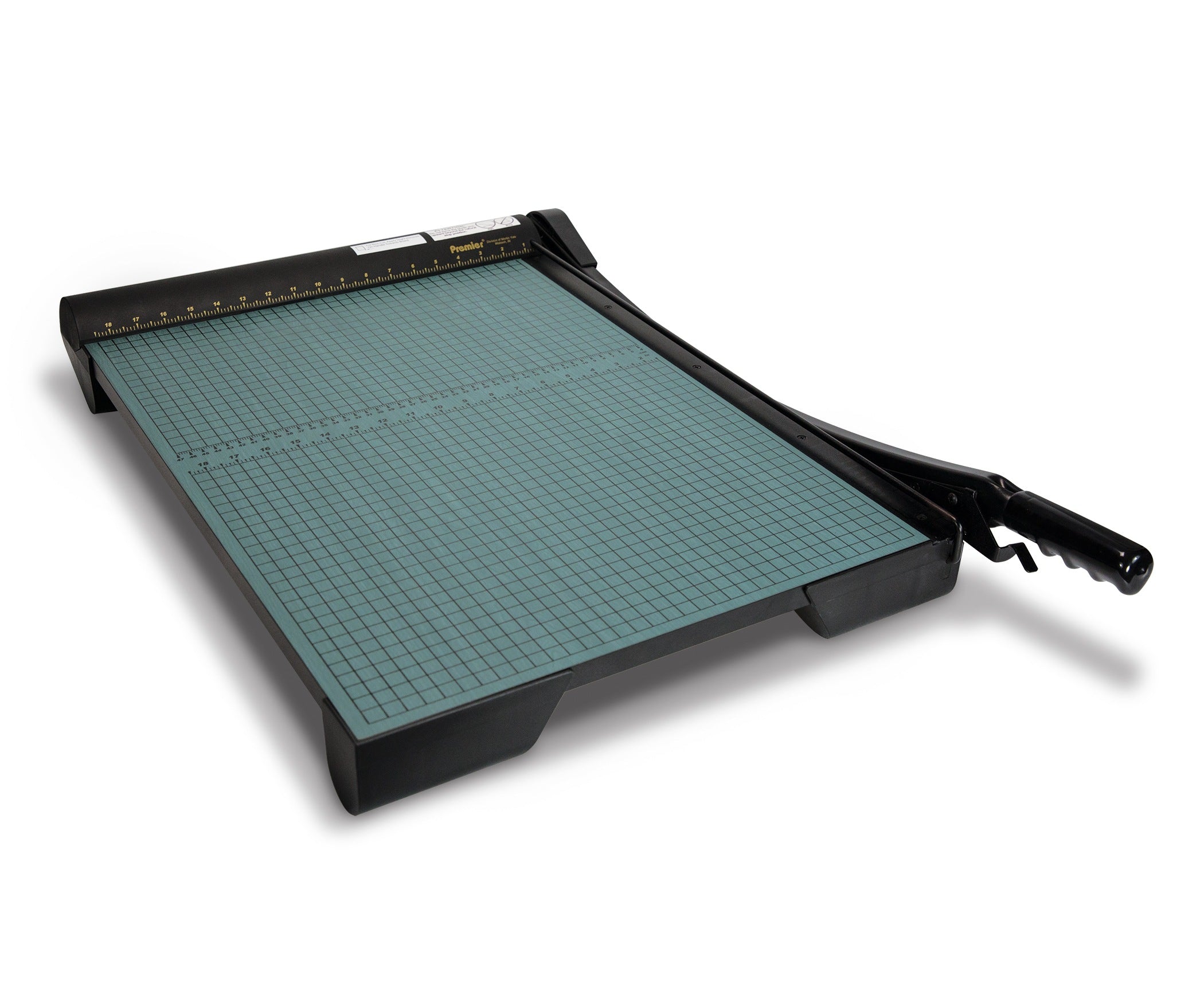

Premier

Martin Yale Premier GreenBoard Heavy-Duty 30" Paper Trimmer

Sale price$455.29

Regular price$895.16

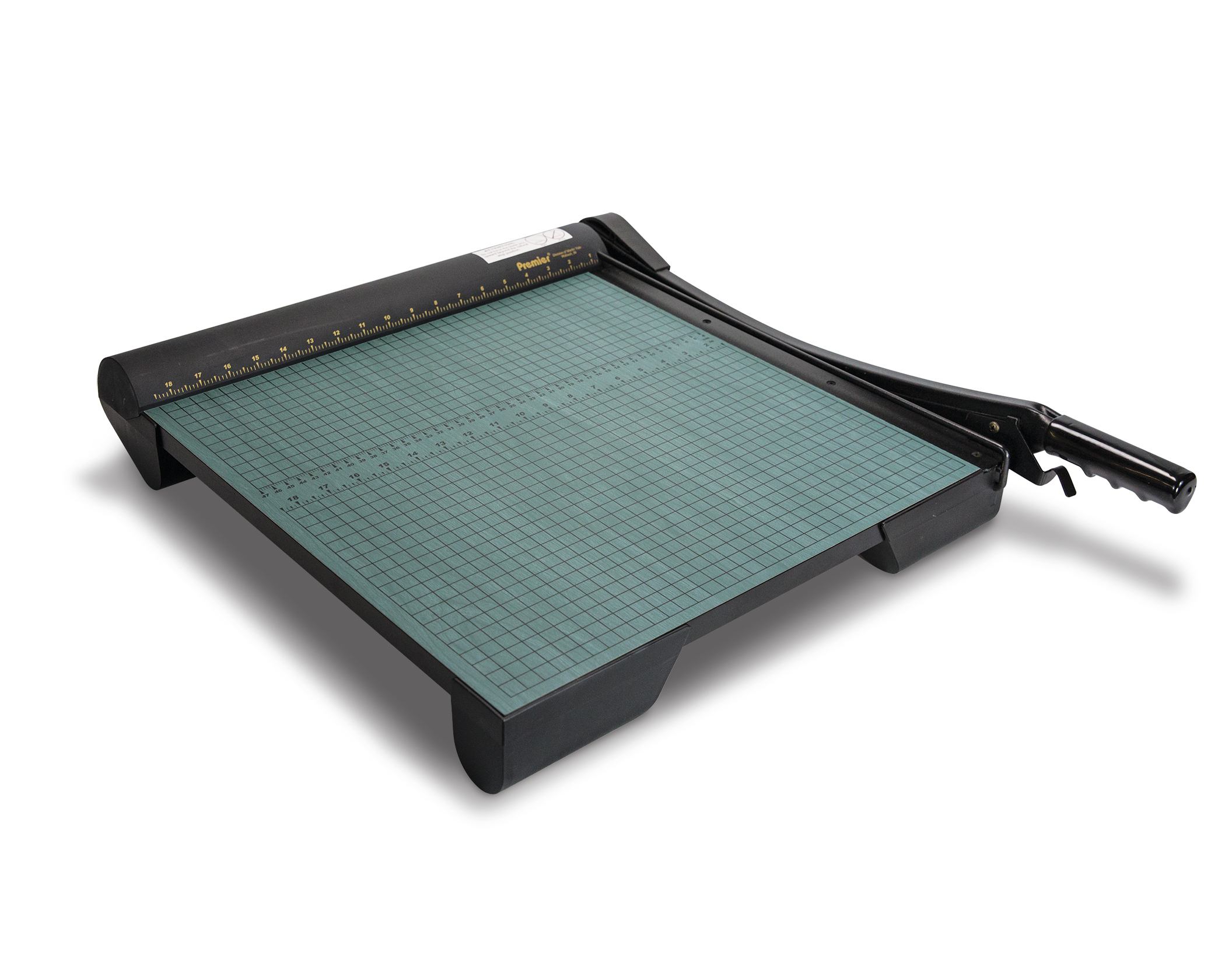

Save $174.85

Premier

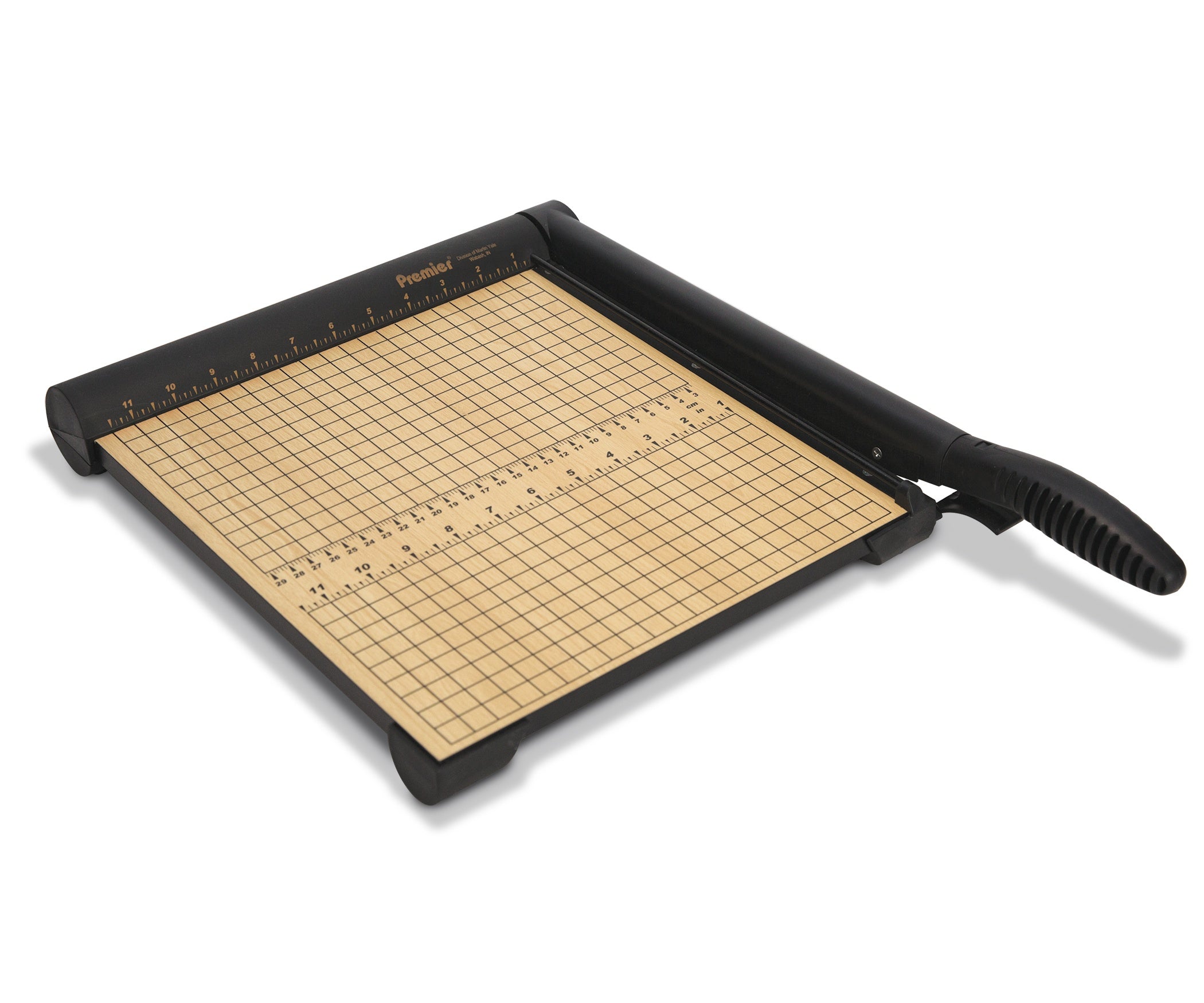

Martin Yale Premier GreenBoard Heavy-Duty 15" Paper Trimmer

Sale price$168.81

Regular price$343.66

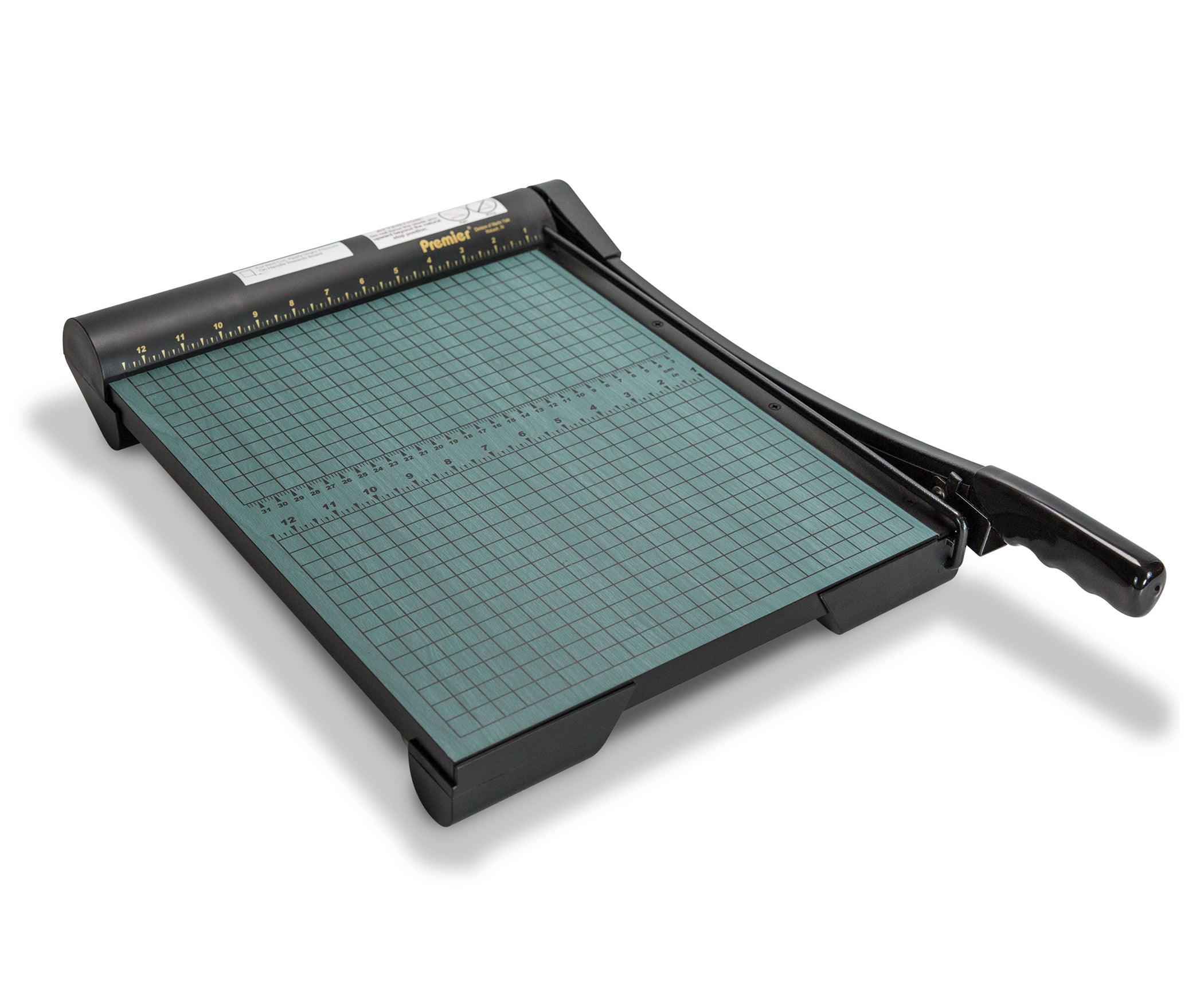

Save $121.60

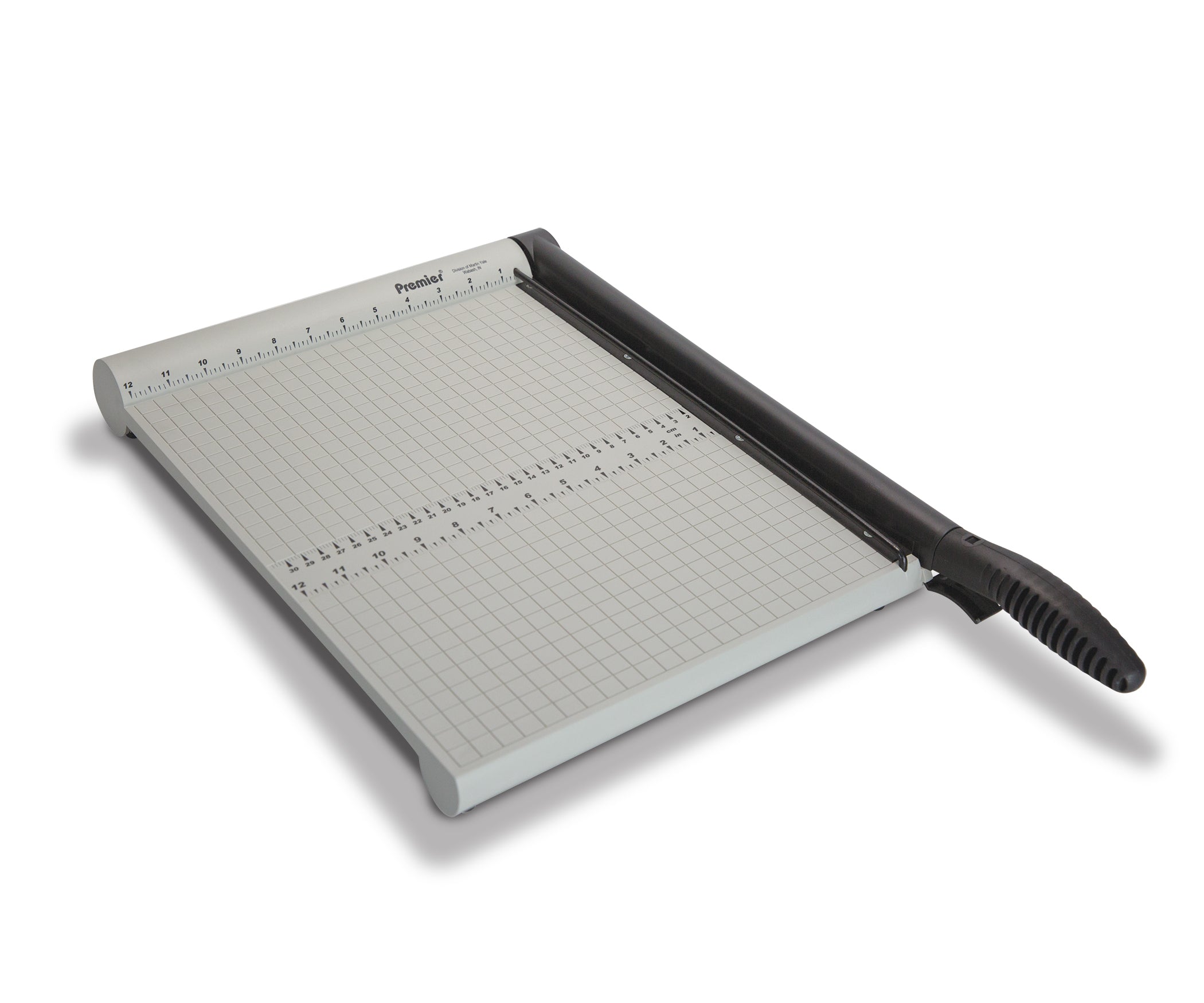

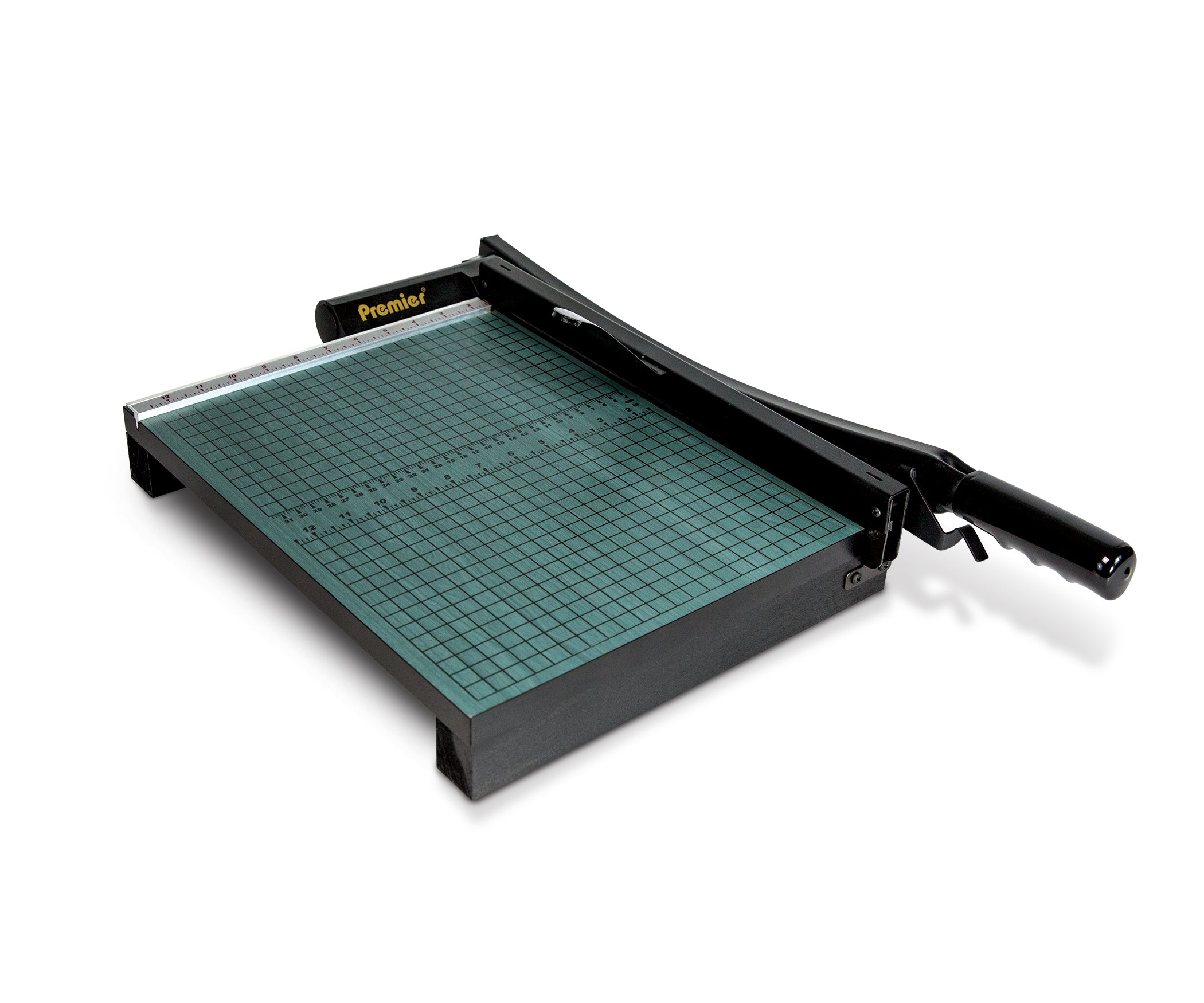

Premier

Martin Yale Premier GreenBoard Heavy-Duty 12" Paper Trimmer

Sale price$120.19

Regular price$241.79

Save $670.25

Martin Yale Office

Martin Yale 7000E Commercial Stack Paper Cutter

Sale price$1,177.11

Regular price$1,847.36

Save $81.57

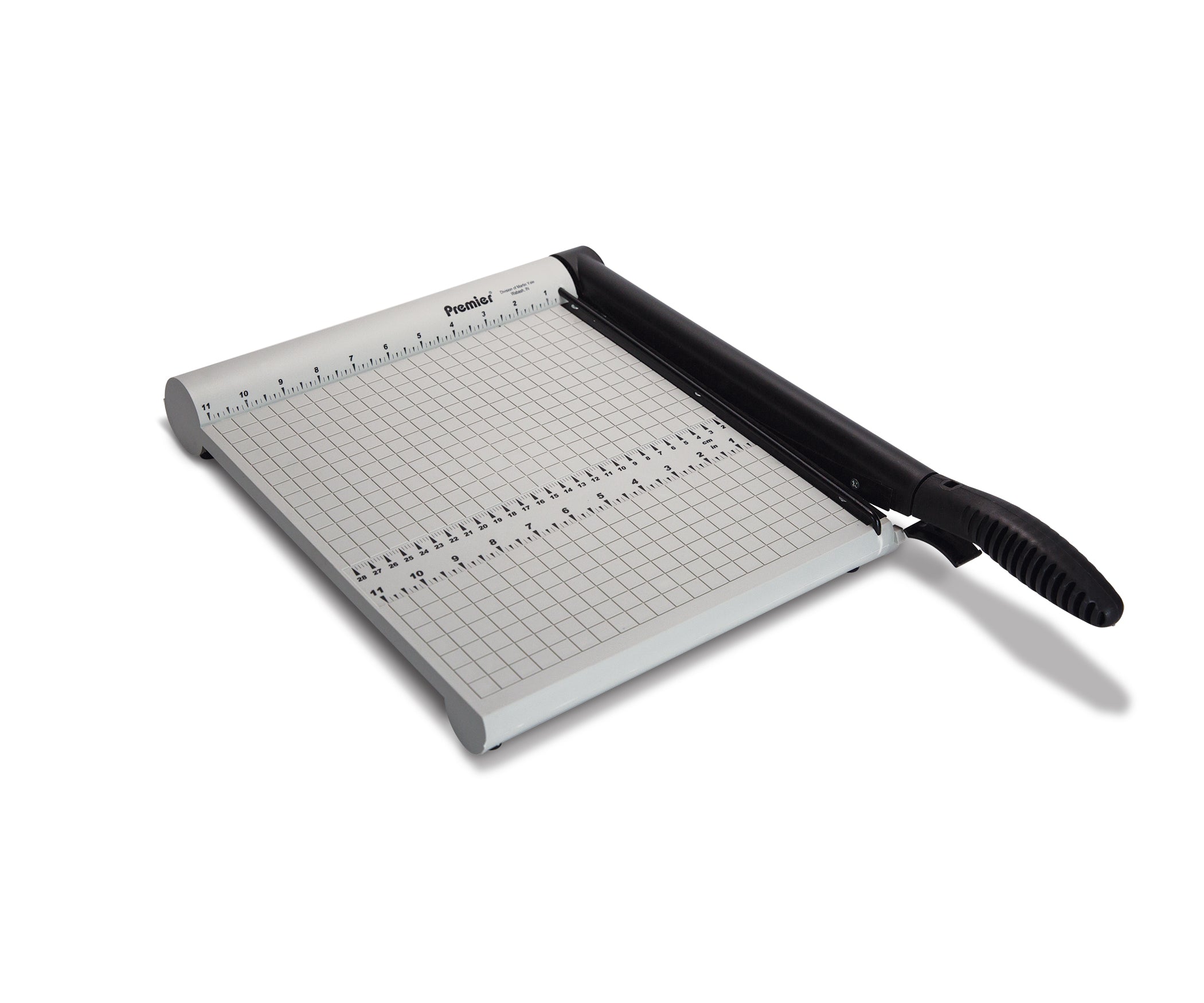

Premier

Martin Yale Premier SharpCut Medium-Duty 15" Paper Trimmer

Sale price$114.03

Regular price$195.60

Save $57.41

Premier

Martin Yale Premier SharpCut Medium-Duty 12" Paper Trimmer

Sale price$79.78

Regular price$137.19

Save $2,198.98

Martin Yale Office

Martin Yale 620RC Manual Ream Paper Cutter

Sale price$3,978.64

Regular price$6,177.62

Save $1,064.56

Premier

Martin Yale Premier GreenBoard Heavy-Duty 36" Paper Trimmer with Cart

Sale price$1,417.25

Regular price$2,481.81

Filters (0)